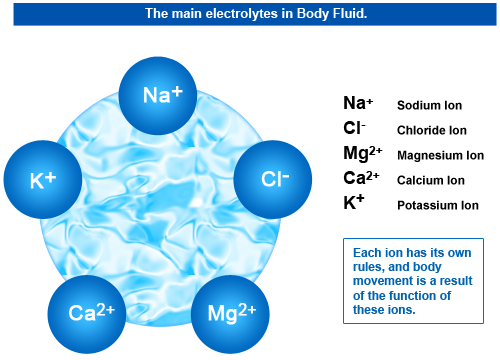

Coating iron or steel with zinc is called galvanization.

Galvanization can be defined as the process of applying zinc to iron or steel through the use of electro chemical and electro deposition process.

Galvanized steel and springs known for its durability, corrosion resistance and more importantly, its affordability.

Galvanized steel is used in products where rust oxidation due to water exposure could degrade the product significantly.

There are two common methods protective coating to the iron springs and the trampoline frame steel tubes.

Methods of galvanizing iron and steel

1.Hot dip galvanizing

PS : image from galvanizeit.org

During this process, the steel or iron parts are submerged into a vat of hot, molten zinc after the surface of the metal has been thoroughly cleaned.

The metals are then left to cool in a quench tank.

This process gives a relatively thick zinc protective coating.

During this process, multiple layered iron- or steel-zinc alloys are formed between the inner surface of the zinc coating and the iron or steel.

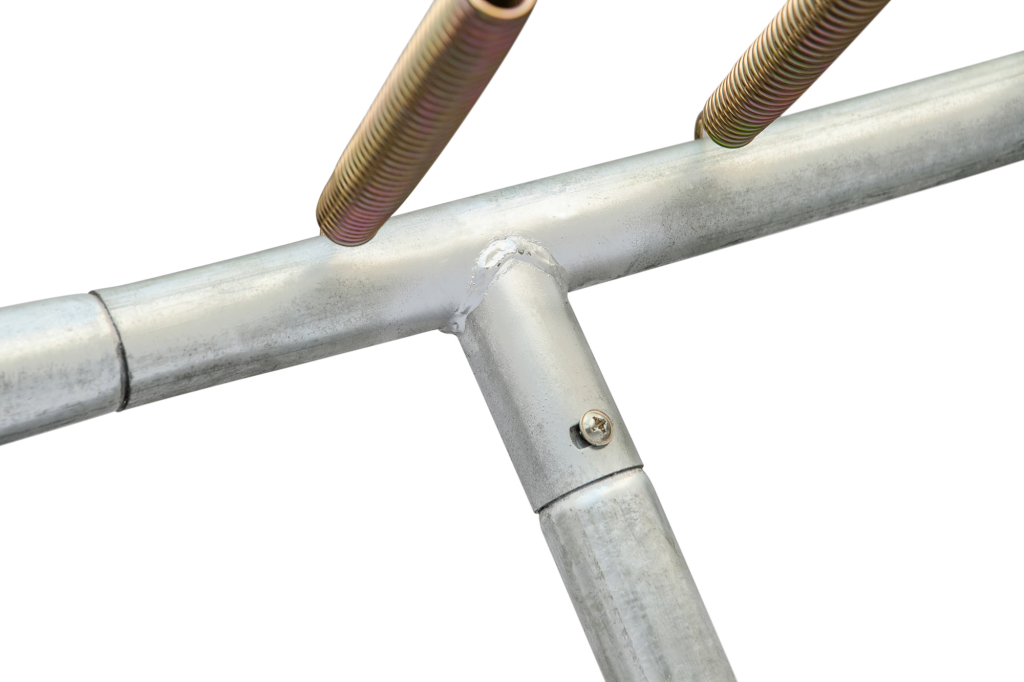

The advantage of this type of galvanizing is that the resulting coated steel or iron can be used just the same way like the uncoated one.

The zinc coated steel frames can also be welded easily,but you have to take the precautionary measures for the zinc fumes.

2.Electro galvanizing

In this method, iron or steel is immersed in an electrolyte.

Electrolytic action deposits coating of pure zinc on the surface of iron or steel.

So why most trampoline factory choose to add zinc layers on the trampoline tube and trampoline spring ?

Check Below Top 5 Benefits :

1.Durable and Long lasting

Research has shown that zinc coated iron and steel last for many year as compared to those that are not coated with zinc.(e.g., those coated with paint) galvanized steel and iron has been in the used for over a century and has been well known for its durability.

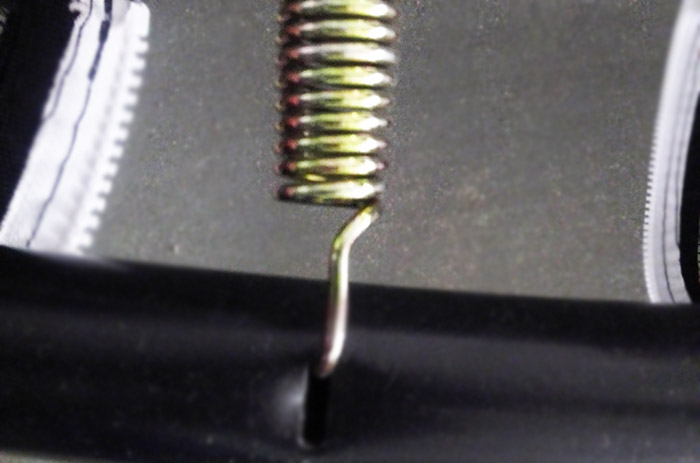

The same case applies to trampoline springs and steel frame tubes.

The process of hot dip galvanizing results in a metallurgical bond between zinc and the surface of these metals.

When the end alloy is exposed to the atmosphere, the zinc on the surface reacts with oxygen to from zinc oxide.

The zinc oxide formed further reacts with carbon dioxide that is present on the atmosphere to form zinc carbonate, a strong material that effectively protects the steel used in making the springs and the trampoline steel frame pads and prevent these metals from corrosion.

Investing your money on a trampoline with zinc coated springs and steel tube is therefore worth your money because the structure will serve you for many years to come.

2.Resistance to Corrosion

The iron springs and steel tubes that are not coated are very corrosive.

Zinc coated trampoline springs and trampoline steel tubes are rust free because a thin layer of zinc is used to cover the surface of these metals.

The zinc coating will therefore prevent the steel tubes and iron springs from corroding due to oxidation of these metals.

Corrosion causes a lot of problems when it comes to maintenance.

It makes the springs and the steel frame tubes to be worn out, making the trampoline structure to be weak.

And because most trampolines are installed outdoor, the galvanized springs and frame tubes are the best option because they will not rust when in contact with air or moisture.

3.Zinc Is a Very Tough Coating And is Scratch Resistant

Zinc coating itself is a unique structure that helps the trampoline steel tubes and springs to be resistant to damage.

The process of adding zinc coating to the iron springs and the steel metal tubes makes these metals stronger.

This enables them to withstand the harshest weather conditions like rain or snow.

Galvanization also protects the steel tubes and iron springs from damage that can occur during transportation, installation and servicing of the trampoline because zinc is scratch resistant.

4.Reliability in Performance

The zinc coating that is added to the trampoline springs and steel frame tubes help to increase the durability of the finished product (galvanized springs and the steel frames).

This makes the springs and the steel frame tubes to be much more reliable and predictable.

Zinc coated steel frame tubes and springs are also stain resistant and fade proof.

6.Low Maintenance Cost

Buying a trampoline with galvanized steel tubes and springs will save you money in the long term.

This is because zinc coated steel and iron provides an easy to clean surface which require less maintenance than other types of coated steels and iron, saving you time and money that will be lost in repairs or replacements of the springs and the trampoline frame tubes.

Conclusion

Nothing more than steel and iron coated with zinc is resistant to corrosion.

Zinc coated springs and trampoline steel frame tubes have an advantage over other methods that are used to coat these highly corrosive metals.

The alloy is also light in weight and it’s very strong.

These products are also fade resistant and stain resistant.

All these good qualities of zinc coated springs and trampoline frame steel tubes make them excellent for both indoor and outdoor use.So zinc coated is very important for many trampoline parts like tube ,spring, pole ,ladders .

Any question , freely let me know.